Should You Steer Clear of Wet Timing Belts?

A Summary of Wet Belts

Recently, a different type of timing belt has gained attention: wet timing belts. These belts, prominently used in Ford's EcoBlue engines, have been causing significant issues in the automotive industry while largely flying under the radar. In this article, I take an in-depth look at this problematic component, exploring its intended purpose, the issues Ford aimed to address, and the challenges that have arisen as a result.

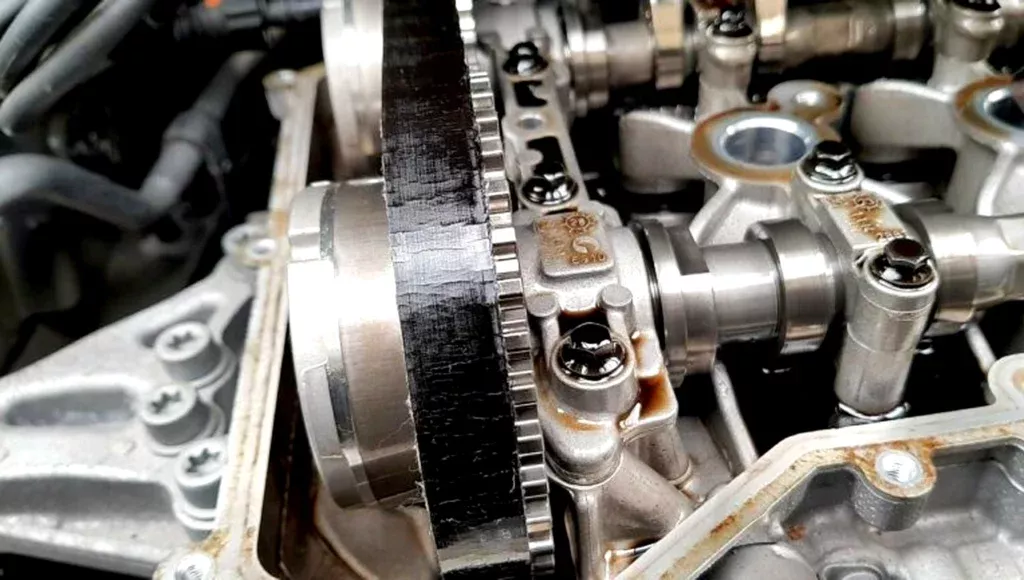

The Wet Timing Belt

A traditional dry timing belt is typically located outside the engine, shielded by a protective cover. In contrast, a wet timing belt is positioned inside the engine, submerged in oil.

The Purpose of Wet Belts:

Extended Maintenance Intervals

- Lubrication from the engine oil reduces wear and friction, potentially increasing the belt's lifespan, improving fuel efficiency, and lowering CO2 emissions.

Improved Heat Dissipation

- Any heat generated by the belt can dissipate into the surrounding oil, helping to regulate engine temperatures.

Reduced Noise

- Noise and vibrations from the timing belt are dampened by the oil, contributing to quieter engine operation.

The first "belt-in-oil" system appeared in European-market Ford 1.8L diesel engines (1.8 TDCi). Volkswagen soon adopted the concept in certain EA211 and EA288 engine families. Ford later integrated wet belts into its EcoBoost engines in 2010 and expanded their use in 2016 with the launch of the EcoBlue engine, which powers a wide range of vehicles.

However, one of the primary causes of timing belt failure is fluid contamination, particularly from oil. This is why the "belt-in-oil" system has raised eyebrows. Oil exposure typically degrades the rubber in timing belts, leading to tooth separation or snapping. Combining these two elements in the same system may seem counterintuitive and potentially problematic.

To minimize the risk of issues with wet timing belts, it’s crucial to follow best practices for maintenance and usage. Here are the most effective strategies:

Follow the Manufacturer’s Maintenance Schedule

- Adhere strictly to the timing belt replacement intervals recommended by the manufacturer. Wet belts often have longer replacement intervals, but delaying maintenance can lead to failure.

Use High-Quality Oil and Filters

- Ensure you’re using the manufacturer-recommended oil grade and quality. Substandard oil can accelerate belt degradation. Regularly replace oil filters to prevent contaminants from circulating in the engine.

Check for Oil Contamination

- Inspect the oil for signs of debris, excessive wear particles, or contamination. Any irregularities can affect the wet belt's lifespan.

Address Oil Leaks Promptly

- Even a minor oil leak can disrupt the wet belt system. Regularly inspect the engine for leaks, particularly around seals, and repair them immediately.

Avoid Harsh Driving Conditions

- Consistent heavy towing, aggressive driving, or extreme temperatures can place additional strain on the timing belt and oil system. Operate the vehicle within its designed limits.

Monitor for Warning Signs

- Pay attention to unusual engine noises, vibrations, or performance issues, as these could indicate wear or damage to the timing belt. Address these promptly with a professional inspection.

Choose a Trusted Mechanic

- When it’s time for belt replacement or engine servicing, use a reputable mechanic familiar with wet belt systems. Improper installation can lead to premature failure.

By taking these precautions, you can reduce the likelihood of wet belt failures and maintain optimal engine performance.

What Issues Do Wet Belts Cause?

Wet timing belts were originally introduced to address a key challenge: reducing vehicle emissions. Automakers sought affordable and efficient ways to meet stricter environmental regulations, and wet belts emerged as a compact, quiet solution. These belts provided a 30% reduction in friction loss, improved fuel economy by around 1%, and contributed to lower emissions, making them a promising innovation for the automotive industry.

However, despite their intended benefits, the problems caused by wet belts often outweigh their advantages.

Primary Issues with Wet Belts

Susceptibility to Oil Impurities

- Even minor contaminants in the oil, such as soot or crystalline particles, can accelerate belt wear. This wear results in belt material breaking off and mixing with the oil, which can clog the oil sump filter, leading to oil starvation.

Impact on Engine Components

- A clogged sump filter can cause cascading issues, including damage to the brake vacuum pump. This can lead to reduced braking performance, significantly increasing the risk of accidents.

Challenging Maintenance

- Replacing or maintaining a wet belt is significantly more labor-intensive compared to a dry belt. The process requires draining the oil and disassembling much of the engine to access the belt, resulting in longer repair times and higher labor costs.

While the wet belt was designed to solve efficiency and emissions challenges, its drawbacks—such as premature wear, system contamination, and maintenance complexity—often make it more trouble than it's worth for many vehicle owners.

Does My Motorhome Have a Wet Belt?

If your motorhome is powered by a Ford engine, there’s a good chance it may be equipped with a wet belt, particularly if it features an EcoBoost or EcoBlue engine.

To determine if your motorhome has a wet belt, check the engine:

-

Standard Timing Belt:

Located on the outside of the engine, it should be visible when you look under the hood.

-

Wet Timing Belt:

Positioned inside the engine and submerged in oil, it won’t be visible from the outside.

For a more definitive answer, you can refer to your motorhome’s manual or consult a mechanic.

How Can I Get the Most Out of My Wet Belt?

Dayco, a leading manufacturer of wet belts, emphasizes the importance of regular and proper maintenance to maximize the lifespan of your timing belt. Insufficient oil levels, neglecting routine maintenance, or using the wrong type of oil can negatively impact the belt's performance.

However, it's worth noting that many drivers are experiencing premature wet belt failures. While Ford recommends replacing the belt every 144,000 miles or 10 years, many garages suggest replacing it around 90,000 miles or every 5 years due to these early failures.

Unlike dry belts, which often show visible signs of wear, wet belts are more challenging to inspect. They don’t provide audible warnings before failure since any noise is dampened by the oil. As a result, drivers must rely on other indicators to detect potential problems.

Signs of a worn wet belt include:

- Difficulty starting the engine

- Poor idling or erratic engine performance at high speeds

Although wet belts are less likely to snap, their teeth can become loose, leading to belt slippage and engine desynchronization. A weakened belt may continue to run but will contaminate the oil with debris, further damaging the engine. Regular maintenance and early replacement are key to preventing these issues.